Advanced NDT Compliance Services

Non-destructive testing for pipelines and tanks

Code Compliance

BSI maintains procedures that are compliant to industry standards and regulatory codes. We follow inspection and reporting guidelines for pipelines and petrochemical plants, as well as refining and chemical facilities.

Guided Wave Testing (GWT)

Guided wave testing (GWT) is an advanced NDT method utilizing ultrasonic technology (UT) to accurately locate corrosion on piping from remote locations. Guided waves travel in both directions along the pipe to perform long range inspection from a single location.

Advanced NDT Compliance Services

Advanced NDT Methods

- Ultrasound: Compression, Shear Wave, Bulk Wave, Pitch-Catch

- Magnetic Particle

- Dye Penetrant

- Helium Leak Detection

- Visual including borescopes

- Laser Imaging Detection and Ranging (LIDAR)

- Positive Material Identification

- Bolt Integrity Assessment

- 3D Berm Capacity Analysis and Liquid Flow

AST Inspections (API 653)

- Out-of-Service

- Robotic In-Service

- 3D LiDAR Tank Strapping

- Fitness for service

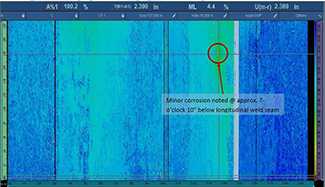

Piping and Pipeline Inspection

- Phased Array: flaw detection, general metal loss, internal pit detection and sizing

- Long Range Guided Wave

- Automated UT Scanning

- ILI collaboration and post-ILI verification

- Corrosion and Erosion Mapping

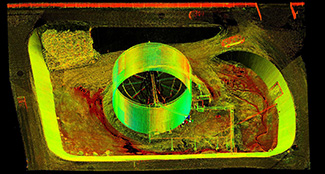

3D Laser Services

- Tank Inspection, Calibration & Deformation Analysis

- 3D models are created from a point cloud data, where each point has its own X,Y,Z coordinate.

- 3D LiDAR provides an accurate tank analysis. Cylindrical tanks and boilers can be unwrapped, and deformation analysis can be performed.

- Precise volumes can be calculated with consideration of deadwood.

Request a Quote