in Data Analytics

in Data Analytics

Predictive Analytics

Continuous Data Monitoring

BSI analysts and statistical algorithms monitor our customer data continuously yielding descriptive trends that serve as predictors of future outcomes. BSI utilizes data science tools and machine learning algorithms to identify potential future outcomes gleaned from historical data and customer feedback.

We use a range of predictive analysis tools to identify and classify data patterns, facilitating risk identification, repair and mitigation.

IMPAcT™ - AI

IMPAcT™ is the heart of a customer’s monitoring network. Real time and archived data are reviewed and correlated with process events. Traditional statistical tools are provided to view operating and inspection histories.

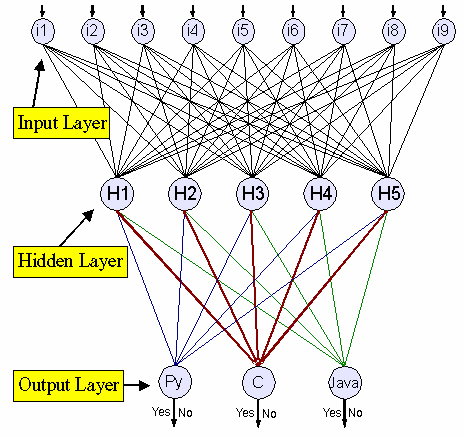

Machine learning tools tap into IMPAcT’s AI libraries to develop mechanical integrity risk profiles.

- Real-time data monitoring

- Machine learning-driven risk profiles

- Customizable alarm thresholds for material thickness changes

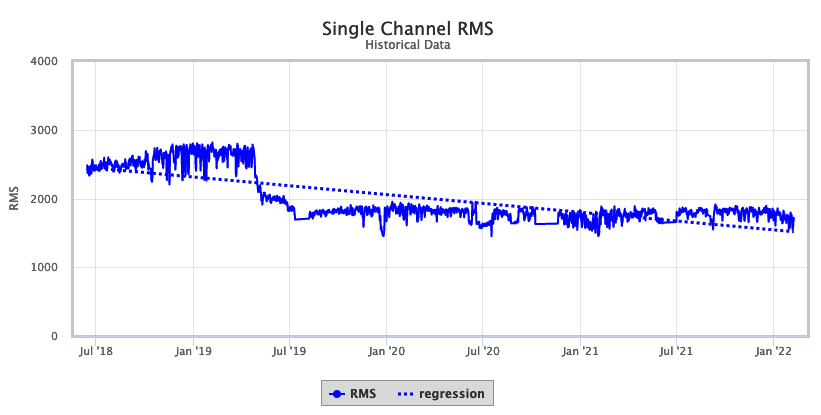

Regression analysis evaluating the relationship among variables.

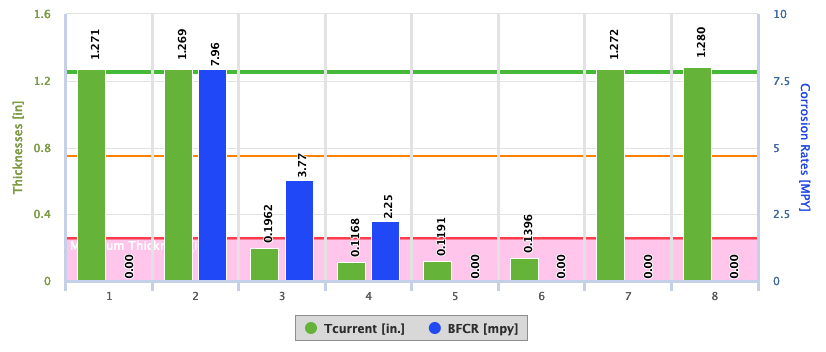

Real-time absolute material thickness and metal loss. Alarms set to notify unusual trends in material thickness and rate of change events.

Machine learning models implemented to identify patterns and make sense of nonlinear relationships often found in mechanical integrity data.