Protection

Protection

The Condor™

Storage tank floor cathodic protection solution

Extend the lifespan of your tank floor bottom with a scalable cathodic protection system designed for your needs.

Advanced AST Bottom Cathodic Protection Solution

The Condor™ provides reliable current distribution evenly across the surface of a tank bottom. Scaled to fit any size tank, The Condor™ can be installed under new tanks, during tank bottom replacements, or retrofitted under current tanks.

Installation of the Condor™ can coincide with planned construction activity schedules. We design Condor™ systems with construction schedules in mind to avoid disruptions for tank owners.

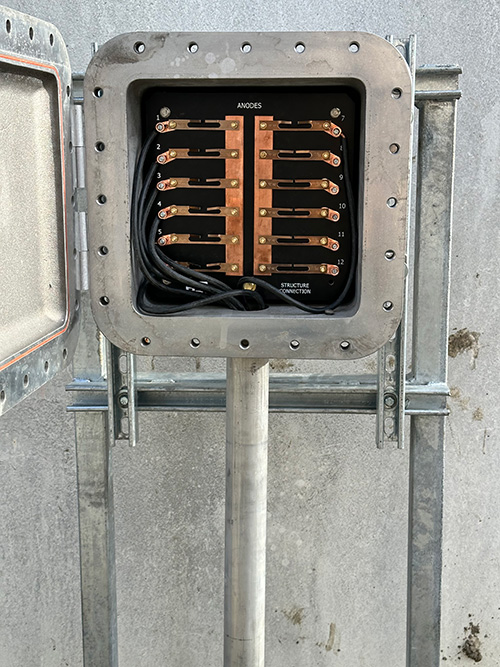

Condor™ Features

- Anode symmetry ensures even current distribution across the tank floor

- Lower electrical resistance compared to similar systems, allowing for the use of air-cooled instead of oil-cooled rectifiers

- Each loop can be operated independently or electrically disconnected

- More anode wire length and diameter than traditional systems results in low groundbed resistance and optimal current distribution

- Mixed metal oxide (MMO) anode with customizable options including coke breeze socks

BSI Engineers will work with your team to design your custom Condor™ system.

Pairing with a BSI Remote Monitoring Unit (RMU) provides a complete solution for tank cathodic protection and corrosion monitoring.

Lower electrical resistance compared to similar systems, allowing for the use of air-cooled instead of oil-cooled rectifiers.

Design Advantages

Condor™ installation can be coordinated with construction activities for minimal disruption of construction schedules.

The Condor™ can be scaled to fit tanks of any size.

Use Condor™ to extend out-of-service tank inspection intervals and meet regulation requirements.

Includes tank floor soil-side corrosion rate and CP effectiveness monitoring.